ADSORPTION PROCESSES BASED ON OUR ADSORBENT MATERIALS:

DESIGNED AND PRODUCED FOR THE EXTRACTION AND CONCENTRATION OF DISSOLVED CONTAMINANTS.

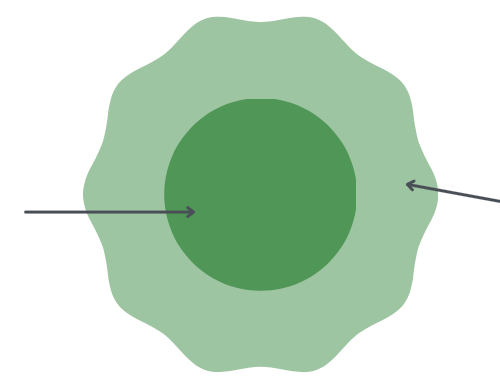

SPHERES AS EFFICIENT SUPPORTS

The sphere acts as a support for the coatings that allow contaminants to be adsorbed on the surface of the particles.

OPTIMIZED COATING AGENTS

The coating allows us to adsorb and release contaminants. This way we can reuse the adsorbent and manage ultra-concentrated waste.

Waste Reduction

One of our greatest advantages is that we can wash and reuse our adsorbent cheaply and easily, as well as releasing ultra-concentrated contaminants in the process, reducing the waste generated by orders of magnitude.

By reusing our adsorbents and avoiding the generation of rejection waters in the process, we reduce by more than 95% the amount of by-products generated that must be managed later .

Optimized Efficiency for YOU

El proceso de regeneración ha sido validado y optimizado en cada caso para el tipo de aguas y contaminantes específicos de cada sector. Con ello conseguimos, en todos los casos, unas concentraciones de contaminantes por debajo de los límites de reutilización de las aguas.

Costs Reduction

The adsorbents on which our processes are based can be reused, and the compounds released as concentrated solids in the washing process of these materials are easily managed.

All this substantially reduces the cost of wastewater treatment and subsequent management of recovered wastes or by-products.

Among the validated case studies at pilot plant scale, our technology presents the lowest OPEX (operating cost) of all the alternatives analyzed (activated carbon and advanced oxidation processes such as photo-oxidation or Fenton-type treatment).

Sustainability

COMPARISON WITH CONVENTIONAL ABSORBENT MATERIALS

The most widely used materials (activated carbon, zeolites and ion exchangers) on the market today are porous materials that trap contaminants inside them and, once these are saturated, they are either regenerated with concentrated brines or organic solvents that must be managed later, or they are regenerated through expensive and polluting incineration processes, or they are directly discarded because the cost of the washing process ends up being more expensive than the material itself.

Our product approach is different from all this. We develop and manufacture adsorbent materials (with a “d”, not a “b”) based on coated microspheres, where the contaminants are bound to the external surface of the material instead of inside it. This allows these materials to be washed and regenerated easily and economically, thereby reducing the costs associated with the entire treatment process. In addition, we use different coatings for the different families of compounds that we want to extract from water, so that we adapt our adsorbents to the specific problems of each client.

We believe that each problem has an optimal solution, and that is the only solution we offer to each client.